The chain should be inspected regularly for wear, rust and corrosion. The below guide gives information on how to properly inspect your chain

Visual checks

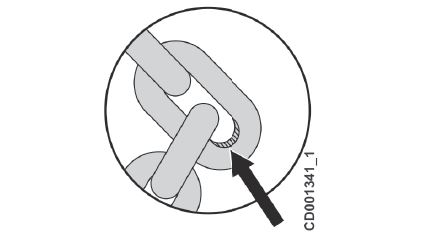

Examine visually for gouges, nicks, weld splatter, corrosion or distorted links and slacken chain. Check bearing surfaces between links for wear. A chain with excessively pitted, corroded, nicked, gouged, twisted or worn links should be replaced with a factory approved chain.

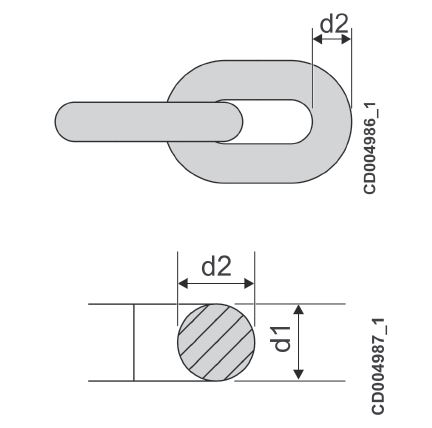

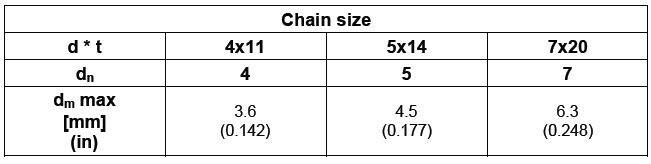

Measure link thickness (d)

Measure the dimension (d) at several points of the chain and calculate the dimension (dm).

dm = (d1 + d2) /2 ≤ 0.9 * dn

dn = nominal

t = pitch

Note: Use only a “knife-edge” caliper to eliminate the possibility of false reading by not measuring full pitch length.

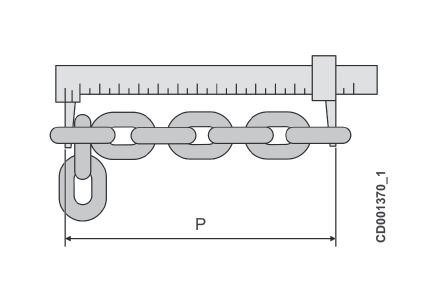

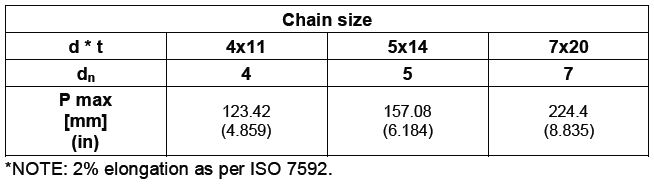

Measure elongation (P)

Measure (P), the pitch over 11 links, at different regions of the chain.

Note: If these limits are exceeded, the chain must be replaced immediately. In this case, wear on the guide chain and chain sprocket should also be checked and they should be replaced if necessary.

Note: if a single link is defective in any way whatsoever, the chain must be replaced.

Do not assume that a load chain is safe because it measures below replacement points given herein. Other factors, such as those mentioned in visual checks, may render the chain unsafe or ready for replacement long before elongation replacement is necessary.

A repetitive stop and start at the same point of the chain will create a more severe wear on the 2-3 links in the chain sprocket.

Still have questions, or want to request a free quote? Contact us today!