Previous Blog: Inspecting Chain Wear

Lubrication is an important part of your equipment maintenance. Lubricate only the instructed components. Other parts are lubricated for lifetime.

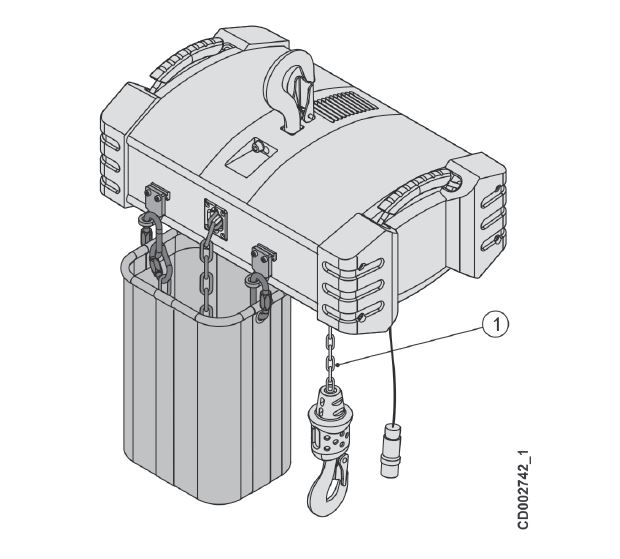

| Pos. | Component | Intervals |

| 1 | Chain | Monthly |

1. Chain

- To extend chain lifetime, lubrication is recommended.

- Lubrication interval varies from month to one year, depending on usage.

- Lubrication shall be done before signs of corrosion or dryness.

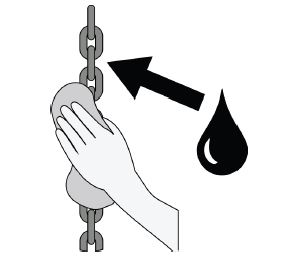

- Lubricate the chain with suitable lubrication. Lubricant for chain shall be water resistant, non-adhesive, transparent thin oil, which is able to penetrate.

- Only lubricate the chain lightly, excessive lubrication my cause dribbling

| Installation | Trade name and number | Quantity |

| Factory installed | Mobile Gear 632 | As required |

2. Gear

Lubricated with oil. Lubrication will last for the designed working period of the hoist.

| Installation | Trade name and number | Quantity |

| Factory installed | Dexron III | Lubricated for the designed working period of the hoist |

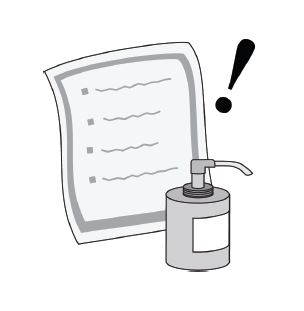

1. Usage of low grade or incompatible lubricant can damage the gearing or bearings. Use only lubricants recommended by the product’s manufacturer. See the lubricant tables for more information.

Use only fresh oils/greases. Different kinds of greases shall not be mixed up.

Information about each chemical’s safe handling, risks and handling as waste are described in the Safety Data Sheet that is available from the manufacturer of the lubricant.

Note: equipment may have synthetic lubricant as a factory installed lubricant. Please refer to the order confirmation.

2. Handle lubricants carefully. Prevent leakages to waters, sewars, cellars and other closed places.

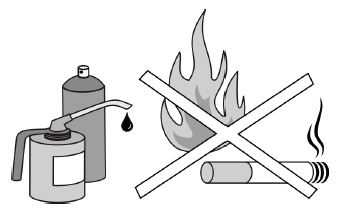

3. Keep lubricants away from heat and open fires. Do not smoke.

4. Avoid contact with skin. Protection gloves and safety goggles should be worn when handling lubricants. Hands should be washed thoroughly after lubrication.

5. Keep lubricants away from food and drink. Do not inhale any fumes or swallow lubricants.

6. Used lubricant shall be handled as hazardous waste following local legal requirements.

Store used lubricant in containers indicated for the purpose and dispose by a licensed company.

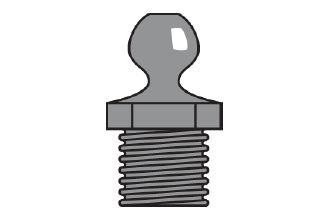

7. Keep grease nipples clean.

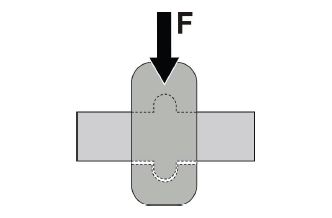

8. All slide bearings must be depressurized for the grease to be able to penetrate.

9. While lubricating, check the functioning of the bearings and observe whether there is any bearing slackness.

10. The specified lubrication periods apply in favorable conditions and normal use. More frequent lubrication is recommended in more demanding conditions and in heavy use.

11. Verify that the gear teeth of the open gear transmission are entirely lubricated.

Still have questions, or want to request a free quote? Contact us today!